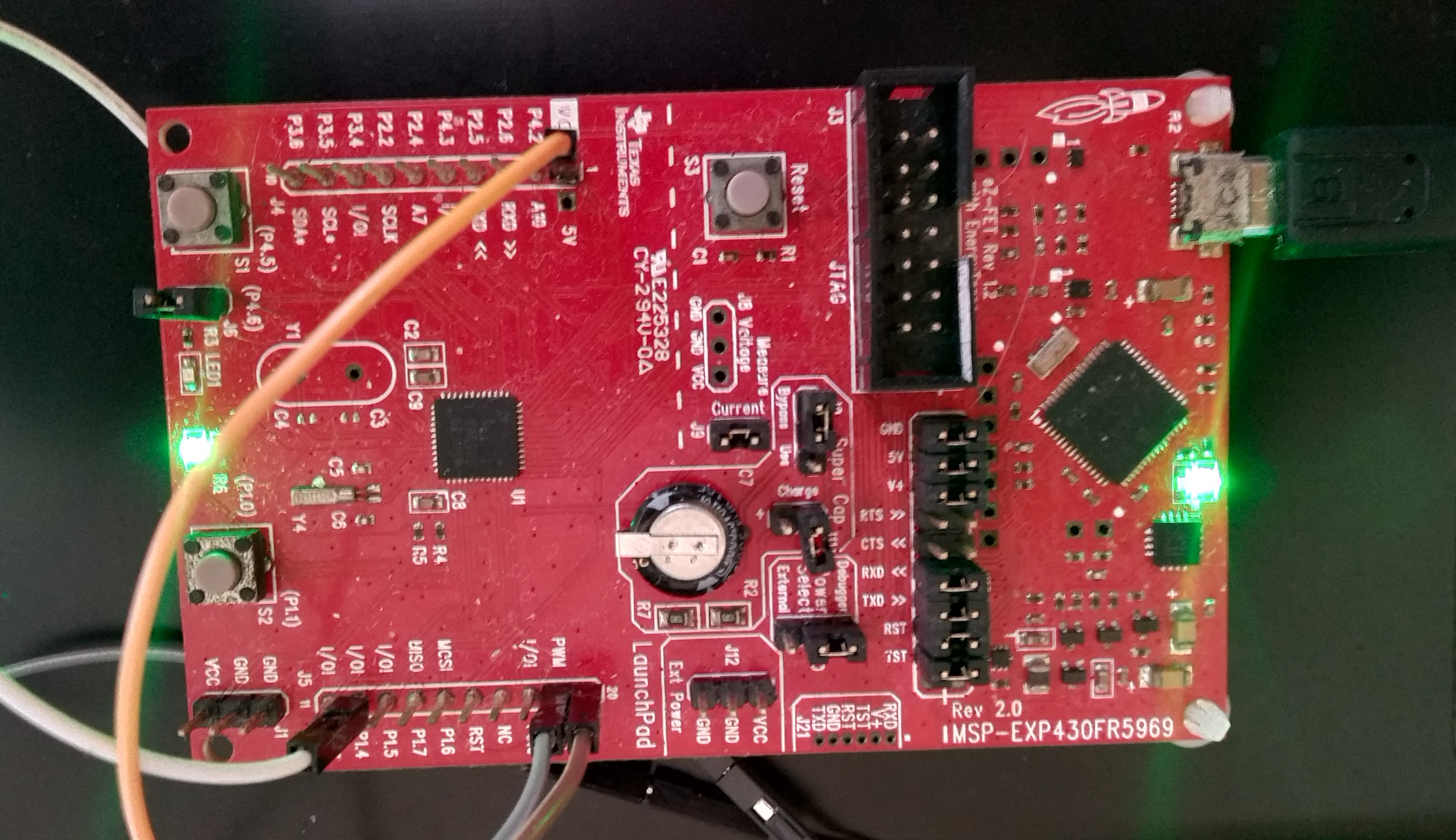

MSP430 Microcontroller using ADC and PWM

It is a simple project using PWM as output and ADC as input in a MSP430FR5969 Microcontroller, in other words, the output voltage (for example a LED) can increase/decrease according to the ADC Value.

The MSP430FR5969 DataSheet and User’s Guide that is used to develop this code. You can find this code here.

Code

CLOCK

As you can see in the datasheet, you can configure different clocks for different utilities, so you can configure the clocks as your project needs. in this case, the MCLK -> DCO = 1MHZ, the ACLK -> LFXTCLK (~32Khz) = 32.768 Hz and the SMCLK -> DCO (1Mhz / 32) = 31.250 hz

// CLOCK

// MASTER CLOCK (MCLK) // CPU CLOCK

CSCTL0_H = CSKEY >> 8; // Unlock CS registers

CSCTL1 = DCOFSEL_0; // DCO = 1Mhz

CSCTL2 = SELM__DCOCLK; // MCLK -> DCO

CSCTL3 = DIVM__1; // Div / 1 (therefore the MCLK clock remains the same)

// AUXILIARY CLOCK (ACLK) // TIMER CLOCK

CSCTL2 |= SELA__LFXTCLK; // ACLK -> LFXTCLK (~32Khz) = 32.768 Hz

CSCTL3 |= DIVA__1; // Div / 1

// SUB-MASTER CLOCK (SMCLK) // ADC CLOCK

CSCTL2 |= SELS__DCOCLK; // SMCLK -> DCO

CSCTL3 |= DIVS__32; // Div /32 (1Mhz / 32) = 31.250 hzPWM

This example project uses the TimerB counter with the Up-Mode, and Reset/set mode. The output is reseted when the timer counts to TBxCCR1 value, and it is set when the timer counts to the TBxCCR0 value, so hence it’s clear that if the relation TBxCCR0/TBxCCR1 changes, the duty cycle PWM will also change.

// Configure PWM output (TIMER B)

TB0CTL = TBSSEL__ACLK | ID__1 | MC__UP | TBCLR | TBIE; // TIMERB -> ACLK , DIV/1 , UP_MODE, Interrupt Enable

TB0CCTL1 = OUTMOD_7; // MODE RESET/SET

//Duty Cycle

TB0CCR0 = 1000-1;

TB0CCR1 = 100; // Duty Cycle = (10%) - initial duty cycleInitialization ADC function:

It’s a 12-bit resolution ADC, therefore N=2^12= 4.096, so the LSB = 3.45v/4096 = 0.0008423 = 0.84mv difference for each bit. as ADC12VRSEL = 0, Therefore VR+ = AVCC (3.45v) and VR-= AVss (0v).

// Configure ADC12

ADC12CTL0 &= (ADC12ENC); // Conversion Disabled for now

ADC12CTL0 = ADC12SHT0_2 | ADC12ON; // Sampling time (16 cycles) and Turn on the ADC

ADC12CTL1 = ADC12SSEL_3 | ADC12SHP; // ADC12CLK -> SMCLK

ADC12CTL2 = ADC12RES__12BIT; // 12-bit resolution

ADC12MCTL0 = ADC12INCH_2 | ADC12DIF; // Channel2 ADC input select; Vref=AVCC

ADC12IER0 = ADC12IE0; // Enable ADC conv complete interruptRead ADC value and change the output

ADC12MEM0 is the register that holds the ADC Value.

while (1)

{

__delay_cycles(5000);

ADC12CTL0 |= ADC12ENC | ADC12SC; // Start sampling/conversion

//while (!(ADC12IFGR0)); // Wait the ADC time sampling

__bis_SR_register(GIE); // Interrupt Enable

__no_operation(); // For debugger

}

}

// ADC12 INTERRUPT

#pragma vector = ADC12_VECTOR

__interrupt void ADC12_ISR(void){

P1OUT ^= BIT0; // Output Led to verify if the ADC interrupt is OK

result = ADC12MEM0;

if(result>=0x0340 && result < 0x0A80){ // ADC >= 822 AND ADC < 2688

TB0CCR1 = 450; // PWM Duty Cycle (45%)

}

else if(result>=0x0A80){ // ADC > = 2688

TB0CCR1 = 900; // PWM Duty Cycle (90%)

}

else{

TB0CCR1 = 100; // PWM Duty Cycle (10%)

}

}

//TIMER B INTERRUPT (B1 VECTOR)

#pragma vector=TIMER0_B1_VECTOR

__interrupt void Timer_B1(void){

TB0CTL &= ~(TBIFG); // Clear Flag

}